PROTECTION FROM DUST AND OILY MIST

Industrial facilities, production lines, state of the art electronic machinery all have a common enemy: floating impurities like dust, oily mists or dirt cover the components of every type of machinery.

Protect Electric Motors, Electronic Machines, Compressors and Heat Exchangers with CATCHER protective filters.

PREVENT DOWNTIME AND REDUCE GENERAL MAINTENANCE COSTS

CATCHER is a family of protective filters that capture floating impurities before they enter your most precious industrial machines. Applying CATCHER to external air intakes or motor fan covers can avoid dust, dirt and oily mists from entering and damaging the components of Electronic Machines, Compressors, Heat Exchangers and Electric Motors.

Catcher filters protect your machines from impurities.

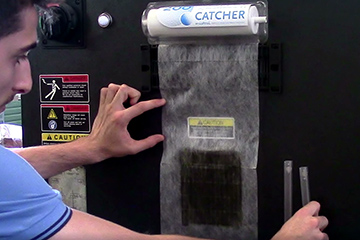

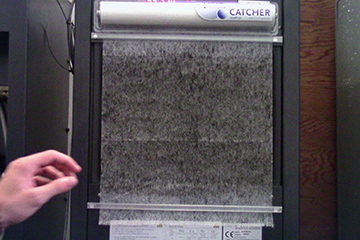

Polluting substances and elements are captured by CATCHER's knitted fabric, thus making easier the preservation of thinner and healthier air inside your facilities. The filter's replacement takes less than a minute to perform. Control of the filter's state is purely visual, reducing the labour time dedicated to ordinary machinery cleaning.

CHINOOK

PROTECTION for ELECTRIC MOTORS

DO NOT GAMBLE WITH DOWNTIME

Protecting your motor's lifetime and avoiding the spreading of suspended particles make the case for using Catcher Chinook. Easy installation and replacement thanks to visual control are the basic reasons for protecting industrial electric motors of diverse sizes with Chinook's patented system.

Equipment cleaning can sometimes become a burdening activity. Oversights, overtime workload, large industrial facilities to inspect: some of the many factors that can dissolve the urgency for care of the machinery. Do not gamble with downtime.

MISTRAL

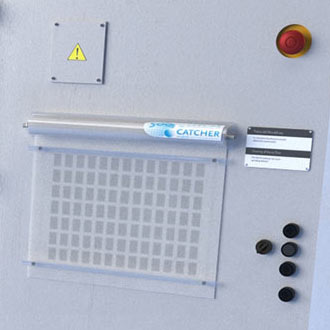

PROTECTION for ELECTRONIC MACHINES

DO NOT GAMBLE WITH DOWNTIME

The packaging, chemical, textile, pharmaceutical and food industries all require maximum attention for asepsis: these environments can't allow the presence of impurities inside sophisticated machines where automation machinery, refrigeration equipment, industrial robots or CNC machines are vital in the production processes.

Protecting the components of cooling systems, air conditioning cabinets, enclosures and electrical panels has never been so simple. Covering the external vents of any industrial enclosures with Mistral is easy thanks to the multiple sizes available.

ZEPHYR

PROTECTION for COMPRESSORS, COOLING SYSTEMS and HEAT EXCHANGERS

DO NOT GAMBLE WITH DOWNTIME

Better air flow is the principal goal of Zephyr's special fabric, designed to stop impurities, dust and oily mists before they enter your industrial compressors and heat exchangers. Protecting with Zephyr the external air intakes and thus lightening any strain for the system, facilitates ordinary machine cleaning.

No switchgear openings and reduction of the possibility of downtime issues are fundamental for interruption-free operation of critical machines like cooling systems.

TECHNICAL CHARACTERISTICS

CATCHER protective filters are created with standard materials to ensure optimal performance. Constant analysis of the feedback from our customers allows us to improve the quality of the filter family, meeting the needs of an industrial ecosystem inclined towards productivity and environmental protection.

Reduce the possibility of malfunctioning, overheating and sudden stops of the machinery used in industrial facilities.

- The filter is applied externally, directly onto the entrance grid of the vent

- Gathers and holds dust and oily mist in its patented-knitted fabric

- Ensures the normal passage of fresh and clean air in the machine

- Protects the engine and avoids the spreading of suspended particles

- Avoids downtime thanks to easy application and replacement

- Visual control allows you to change the filter regularly, ensuring adequate air flow

Chinook TDS

Filter Material for Catcher Chinook

- Type: PRS10A

- Fiber: Polyester

- Colour: WHITE

- Material: Thermobonded

- Weight ISO 9073-1 g/m2: 100

- Thickness ISO 9073-2 mm: 10

- Filter class EN 779: G2

- Initial arrestance EN 779 %: 58

- Average arrestance EN 779 %: 75

- Nominal air flow speed EN 779 m/s: 1.5

- Initial pressure loss EN 779 Pa: 17

- Final pressure loss EN 779 Pa: 250

- Dust holding capacity EN 779 g/m2: 633

- Flammability DIN 53438: F1 / M1

Legend

- LD: Longitudinal direction

- TD: Transversal direction

- LPS: Largest pore size detected

- MFPS: pore size calculated at mean flow

- Units ERT EDANA

- EN or equivalent

Mistral TDS

Filter Material for Catcher Mistral

- Type: PW20W

- Fiber: PLA

- Colour: WHITE

- Thickness mm: 0.14

- Tensile strength Kgf/5Cm/5 cm MD: 3.5

- Tensile strength Kgf/5Cm/5 cm CD: 1

- Elongation % MD: 13

- Elongation % CD: 12

- Tear Strength: 0.2

- Air permeability l/(m2·s): 4800

Tolerance for Catcher Mistral

- Mass per unit area g/m2 40.3 - 90 EN 29073 part 1 ± 10%

- Thickness mm 30.5 - 99 EN 29073 part 2 ± 15%

- Max. tens. strength N-N/50mm 20.2 - 89 EN 29073 part 3 ± 10%

- Elongation % 20.2 - 89 EN 29073 part 3 ± 20%

- Air permeability l/(m2·s) 140.2 - 99 EN 9237:1995 ± 25%

Zephyr TDS

Filter Material for Catcher Zephyr

- Type: 02305

- Fiber: Polyester

- Colour: WHITE

- Mass per unit area g/m2: 25

- Thickness mm: 0.17

- Max. tensile strength dry LD/TD N/5 cm 40/20

- Elongation max dry LD/TD % 18/18

- Air permeability l/(m2·s): 5200

Tolerance for Catcher Zephyr

- Mass per unit area g/m2 40.3 - 90 EN 29073 part 1 ± 10%

- Thickness mm 30.5 - 99 EN 29073 part 2 ± 15%

- Max. tens. strength N-N/50mm 20.2 - 89 EN 29073 part 3 ± 10%

- Elongation % 20.2 - 89 EN 29073 part 3 ± 20%

- Capillary flow porometry micron ASTM F316-03 ± 20%

- Air permeability l/(m2·s) 140.2 - 99 EN 9237:1995 ± 25%

FAQ

The first time I install Catcher filters what should I do?

Before installing Catcher be sure the machine's internal filters are clean.

How long does the filter last?

Depends on the environment and the quantity of pollutants, on average a week.

What happens if I leave the filter mounted even when it is very dirty?

The dirt reduces airflow and this may lead to the overheating of the engine or the electronic system.

THEREFORE IT IS IMPORTANT TO CHANGE THE FILTERS REGULARLY AND TO PERFORM PROPER AND CONSTANT MAINTENANCE.

How to dispose of used filters?

The filters are special waste to be treated like any other industrial waste (oily rags, etc.)

Of what material is the plastic wrap?

Polyester

The filter material is fireproof?

TNT in Mistral is natural self-extinguishing;

TNT of Zephir is chemically treated with flame retardant;

Chinook is flame resistant in accordance to DIN 53438: F1 / M1

What are the differences between Mistral and Zephir?

Zephyr has a higher air permeability and greater ability to retain dust and oil.

Machine protection can sometimes be too time-consuming: urgent deadlines, lack of specialised manpower or even simple omissions may prevent companies from replacing filters regularly. Don't Gamble with Machine Downtime